Super Clear Outdoor and Indoor Eva Film for Architecture Glass

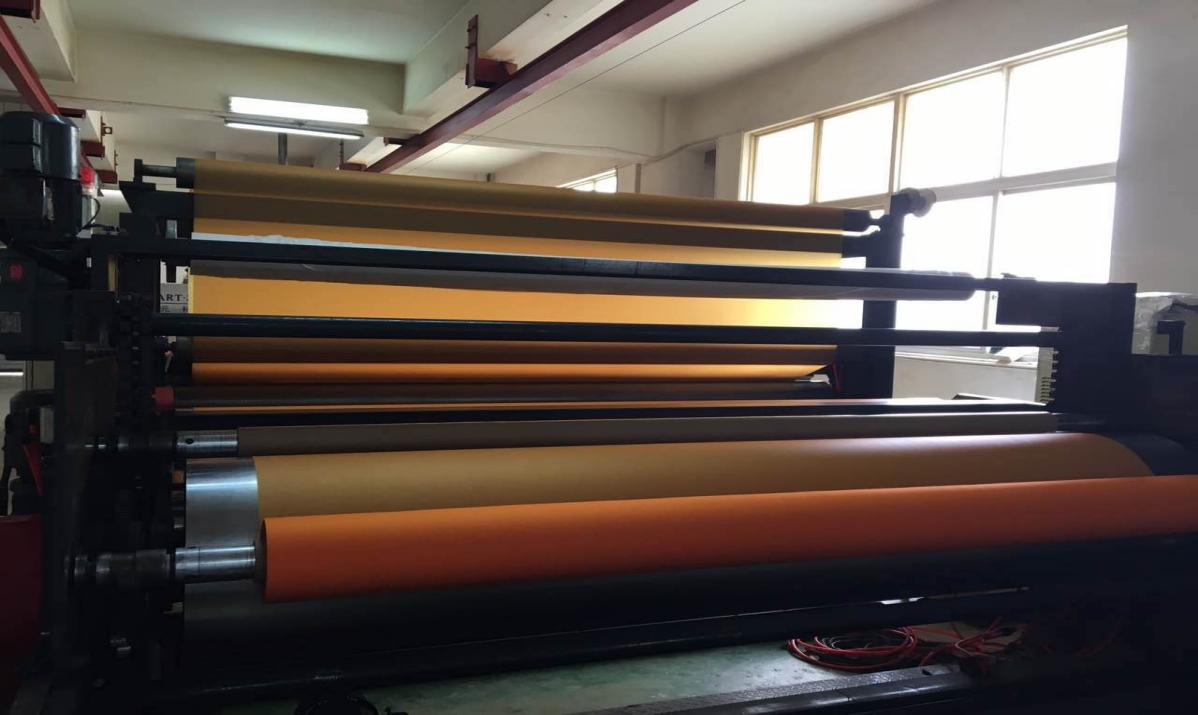

Production process

1.All the film adopts the top quality fresh material.

2.Dust free workshop production

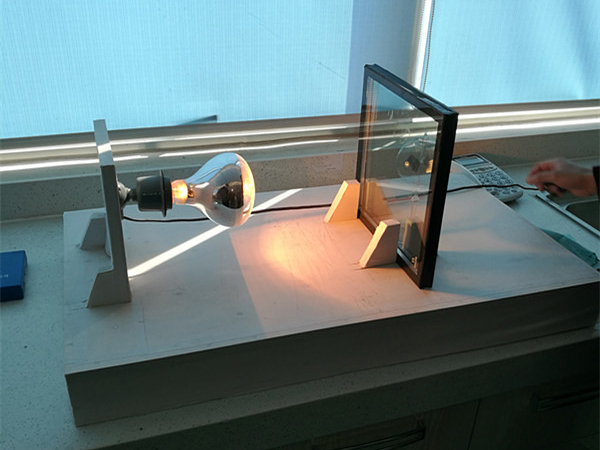

3.Strict quality inspection and test

4.Packing with case or waterproof bag

Technical parameter

| No. | Test item | Test result |

| 1 | Tensile strength | 8.1 MPA |

| 2 | Adhesion with glass | 99.7N/cm(180° peeling) |

| 3 | Adhesion with organic polymer fim | 21.3N/cm(180° peeling) |

| 4 | Light transmittance | ≥90.5% |

| 5 | Haze | 0.47% |

| 6 | UV blocked rate | 90% |

| 7 | Elongation | 800% |

| 8 | Shrinkage | ≤5% |

| 9 | Water absorption | ≤0.01% |

| 10 | Heat resistance

(In the 100°C water for 5 hours ) |

No bubbles,no de-lamiantion |

| 11

|

Humidity resistance

(60°C,95% RH 400 hours ) |

No bubbles,no haze |

| 12 | Anti-aging

(RH radiation 3000 hours ) |

Light change ≤3.0%,no yellow change |

| 13 | Hot & cold shock

(40°C 30 minutes and 80°C 30 minutes for 50 circles) |

No bubbles,no de-lamiantion |

| 14 | Impact resistance against Shot-bag | Qualifiled |

| 15 | Ball impact peeling resistance | Qualifiled |

| 16 | Usefull life | ≥18 years |

Application

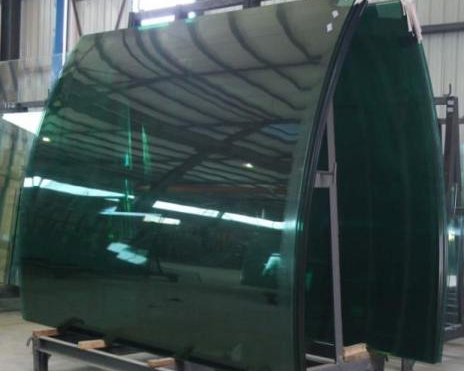

1. Architectural Laminated Glass

2. Building curved laminated glass

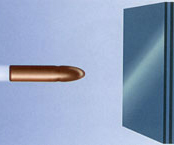

3. Bulletproof glass

4. Real flowers &feather&leaf laminated glas

5. Wire and cloth laminated glass.

6. Colored film laminated glass

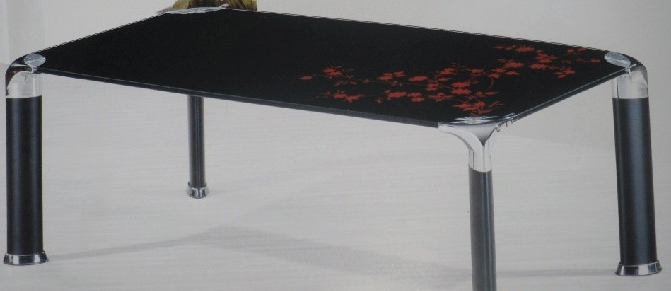

7. Coffee table glass and window glass of cabinet

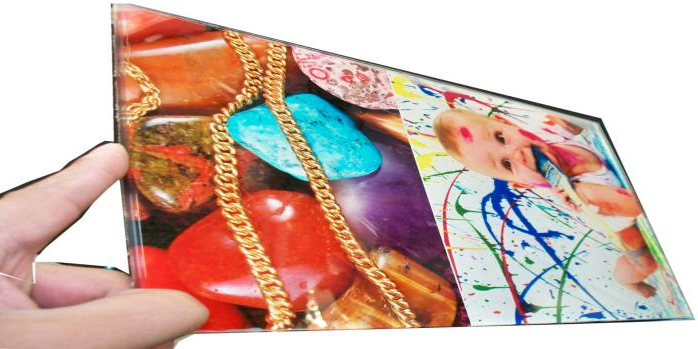

8.Photo and picture laminated glass.

9. Tempered lamianated glass and closet doors.

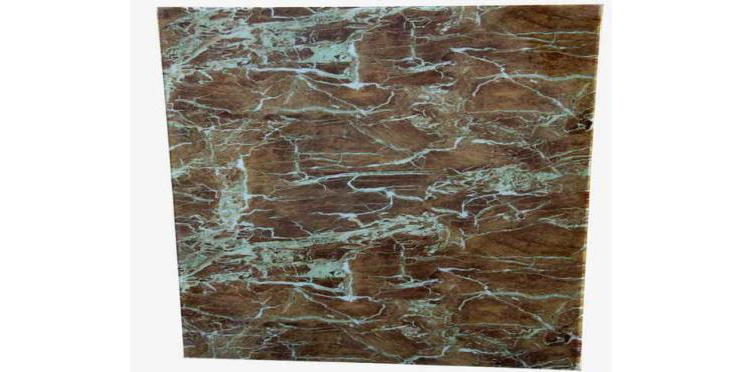

10. Marble laminated glass

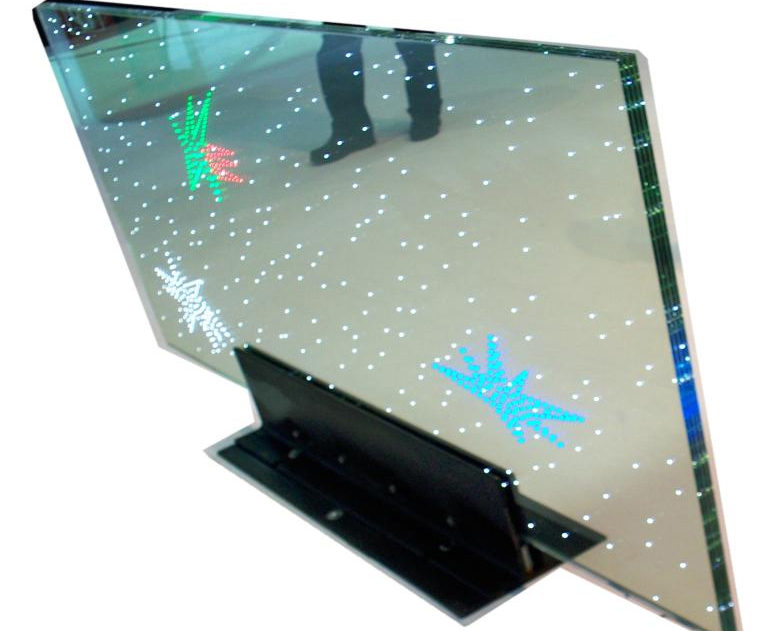

11. Solar PV panels laminated glass, LED glass and electric glass.

12. Polyvision privacy glass

Workshop

Loading pictures

Customer plant

Customer satisfaction

Write your message here and send it to us