GLASS AUTOCLAVE

Introduction

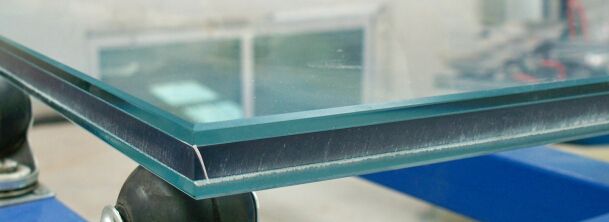

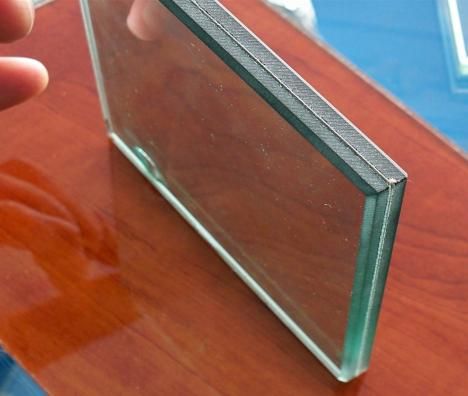

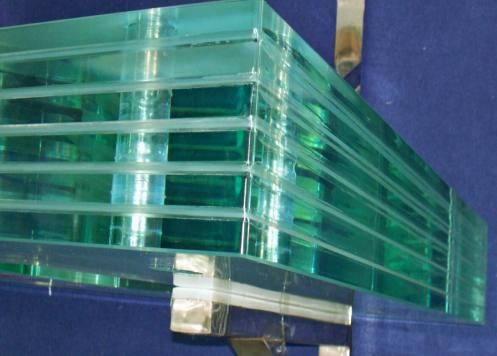

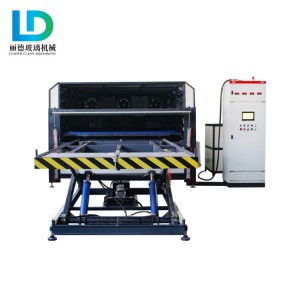

Glass autoclave is the key equipment for laminated glass production, through heating, pressurizing, cooling and others processes, laminated glass securely glued together. It is widely used in producing some special bulletproof glass or other laminated glass with pvb/sgp/tpu film.

Applicable enterprises: The enterprise with bigger proportion and capacity and many years production experience in the glass field and should better have the tempered glass furnace. It is equipped with the heating and cooling system and through the autoclave body insulation and control system composed of 2 parts.Leader autoclave has short processing time and high efficiency. All process is according to our operation rules which use the separate material and could avoid the fire happen. the sealed doors, cooling, autoclave doors and other parts of machine failure maintenance rate is lower. PLC-touch screen control which is more accurate and easy to operate.

Operation steps

Main technical parameters

|

Description |

Specification |

||

|

|

Unit |

LDAT2850 |

|

|

Inner diameter |

mm |

2850 |

|

|

Effective length |

mm |

6000 |

|

|

Max. glass size (small amount) |

mm |

2500*6000 |

|

|

Max. pressure |

Mpa |

1.5 |

|

|

Max. temperature |

℃ |

150 |

|

|

Operating pressure |

Mpa |

1.25 |

|

|

Operating temperature |

℃ |

135 |

|

|

Orbital distance |

mm |

1000 |

|

|

Installed power |

KW |

120 |

|

|

Cycle time |

h |

4-6 |

|

|

Cooling water volume |

m³ |

30 |

|

|

Hold time |

min |

30-45 |

|

|

Compressor power |

kw |

55 |

|

|

Cable cross-section area |

m㎡ |

3×95+1 |

|

|

Dimensions(L×W×H): |

mm |

7500×3200×3250 |

|

The safety laminated glass