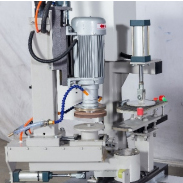

Automatic Glass Chamfering Machine

Equipment details

1.The motor unit adopts domestic famous brand motors to ensure stable operation throughout the year. The layout is optimized and the chamfering is more labor-saving. it is very hard work if you still polish and chamfer glass by hand which is easy hurt and operate slowly.

2.Simple operation, rough grinding and polishing can be completed at one time. It could solve the keen-edged glass hurt the workers and let glass become rounded and beautiful easily.

3.Automatic oil pump, for the screw guide rail, often oiling to reduce damage and water separation.

4.With PLC control, it can control the number of rough grinding and polishing. The width of the equipment can be adjusted automatically.

5.The grinding wheel is independent, the grinding wheel is small and adjustable, and different angle grinding tools can be replaced. The rough grinding and polishing are integrated to reduce the replacement of grinding wheels.

Equipment model and specification

| 1 | Model | LDC-2500 |

| 2 | Reverse R angle number | R5-R50MM |

| 3 | Maximum processing width | 2500mm |

| 4 | Minimum processing width | 350mm*200mm |

| 5 | Glass processing thickness | 3-19mm |

| 6 | Total power | 5KW |

| 7 | Dimensions | 4180*1000*1680mm |

| 8 | Total weight: | 1500kgs |

Loading pictures