2022 High quality Laminated Glass Production Line - laminated glass machine 4 layers – leader

2022 High quality Laminated Glass Production Line - laminated glass machine 4 layers – leader Detail:

Product advantages

1.Stronger. our machine is nearly 1000kgs heavier than others. It adopts famous brand of electrical device & spare parts. We never make the poor quality machine .

2. Mainly exported. Our glass laminating machine are exported to over 40 countries in Europe, America, Asia, Africa and Oceania. Good quality is proved by all our customers

3. High qualified rate. For common glass laminating machine,the qualified rate is only 30%-50%,and there are many terrible problems such as glue overflow, bubbles or poor transparency.The internal structure of our laminating machine and the proper operation data in our PLC can ensure the temperature difference inside the furnace is only 1-2 degrees or so,which make it possible to get top quality products easily.

4.Lower cost. We use environmental materials which has high temperature resistant and warm-keeping ability. What’s more, the Vacuum pump can start and stop automatically according to the pressure set in the PLC,which not only can prolong the service life of the pump,but also save much energy.Good materials and mature technology is very important for a good machine.

5. Good service and longer warranty period.Famous brand appliance and intelligent control system guarantee our machine a much longer service life.

6.We accept customization, we have very experienced technical team which could design the ideal machine according to your requirements.

Operation steps

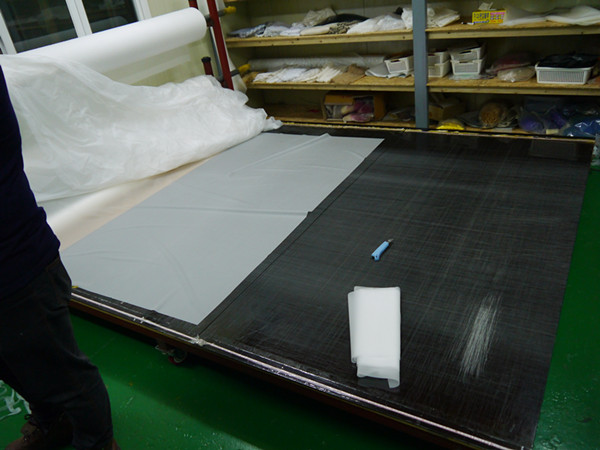

Step 1

Prepare the glass and EVA film.Select the appropriate size of glass,make sure that the glass is clean and dry.Then put the glass on the combination table to combine the glass with the film.Fix the glass well with high temperature tape.

Step 2

Put the glass between the high temperature cloth and seal the silicone vacuum bag well.Then vacuum.

Step 3

Push the tray into the heating chamber and vacuum again.

Step 4

Set appropriate parameters according to the thickness and type of glass.

Step 5

The machine will automatically vacuum and heat, and stop automatically after completion.We can take out the glass from the vacuum bag after it cools slightly.

Application

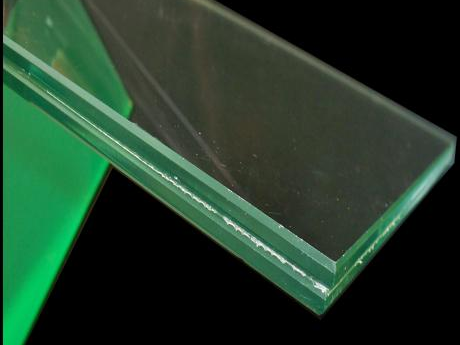

1. Architectural Laminated Glass

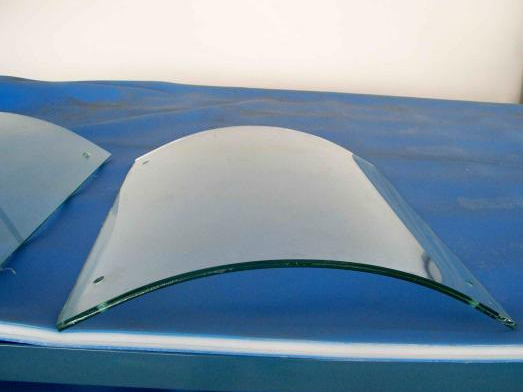

2. Building curved laminated glass

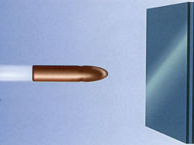

3. Bulletproof glass

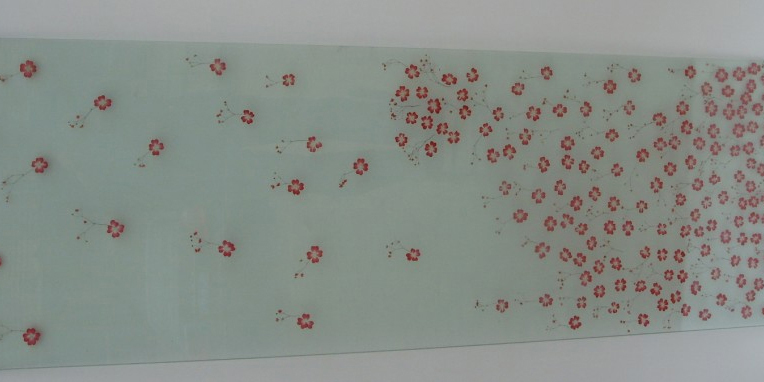

4. Real flowers &feather&leaf laminated glas

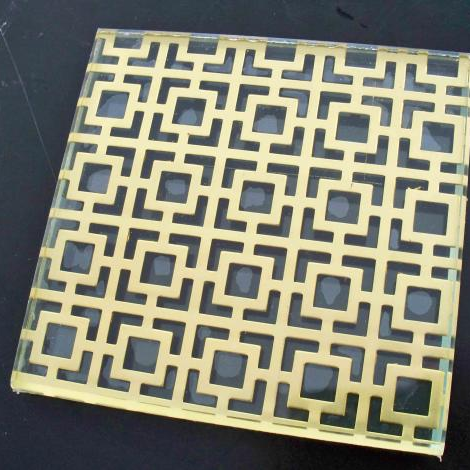

5. Wire and cloth laminated glass.

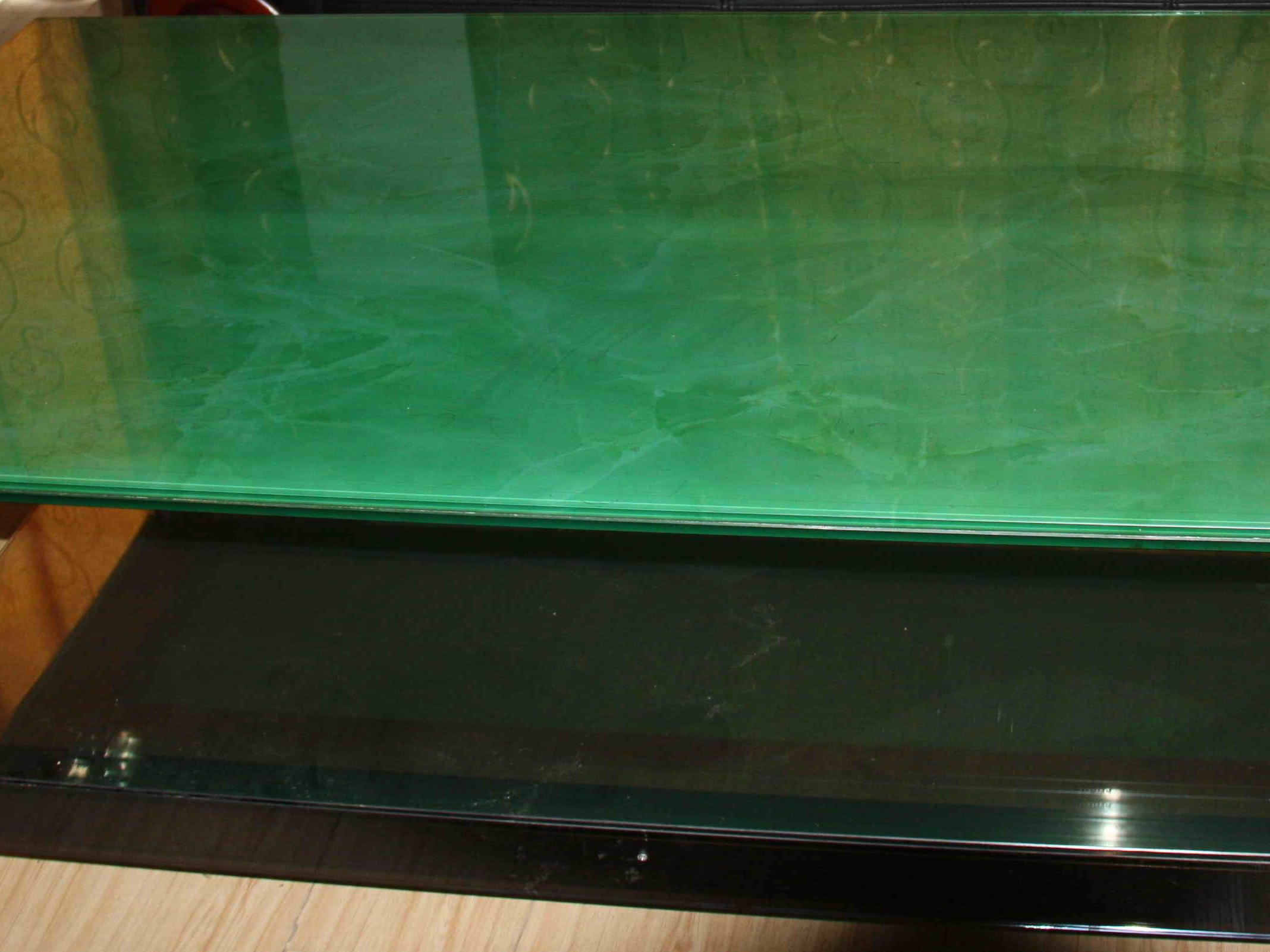

6. Colored film laminated glass

7. Coffee table glass and window glass of cabinet

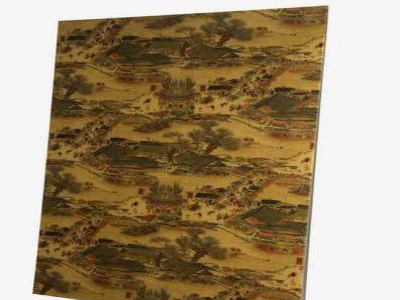

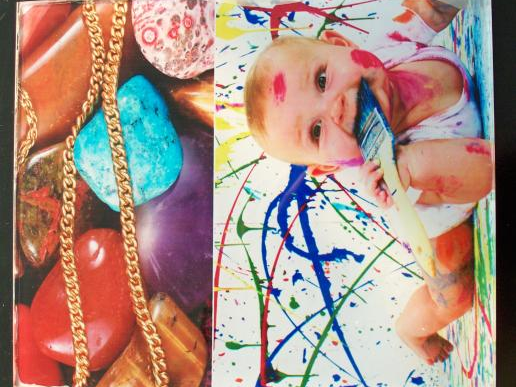

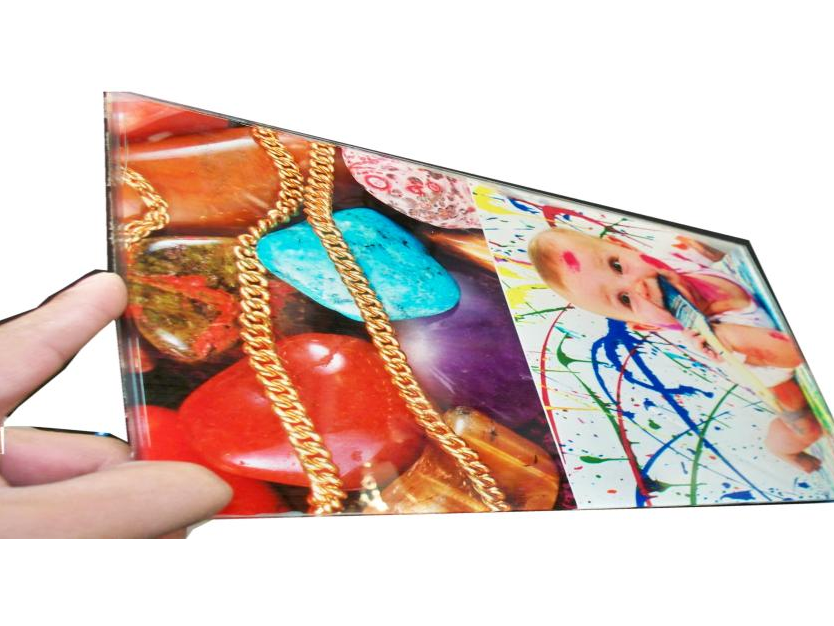

8.Photo and picture laminated glass.

9. Tempered lamianated glass and closet doors.

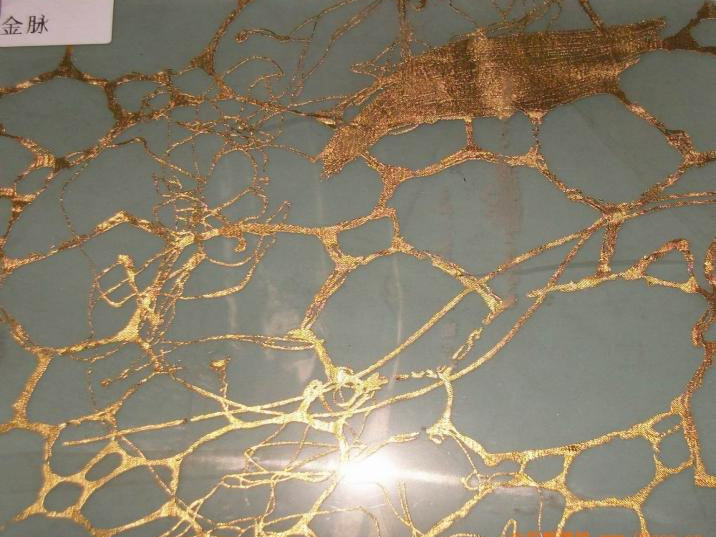

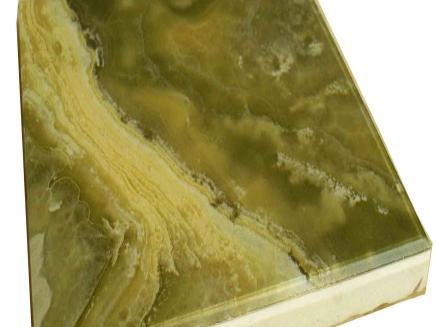

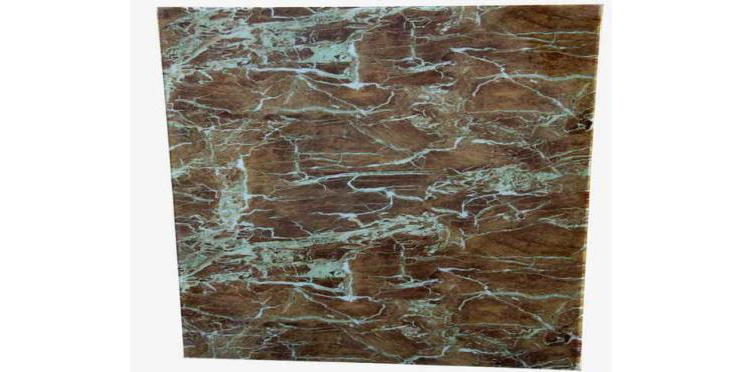

10. Marble laminated glass

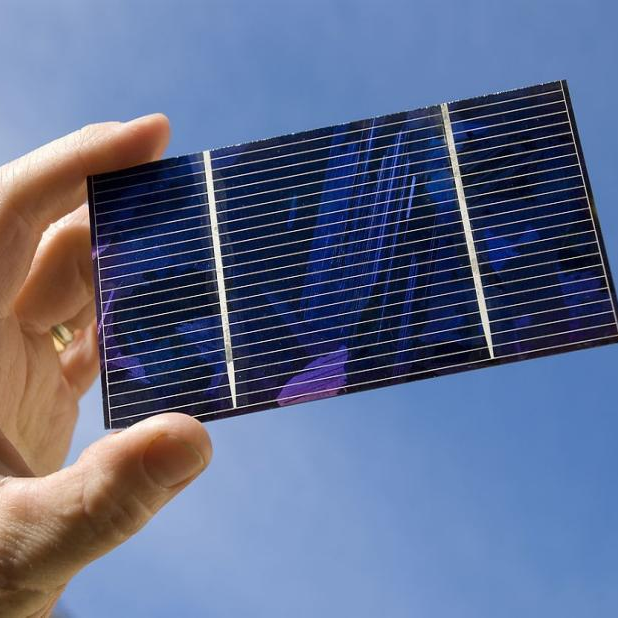

11. Solar PV panels laminated glass, LED glass and electric glass.

12. Polyvision privacy glass

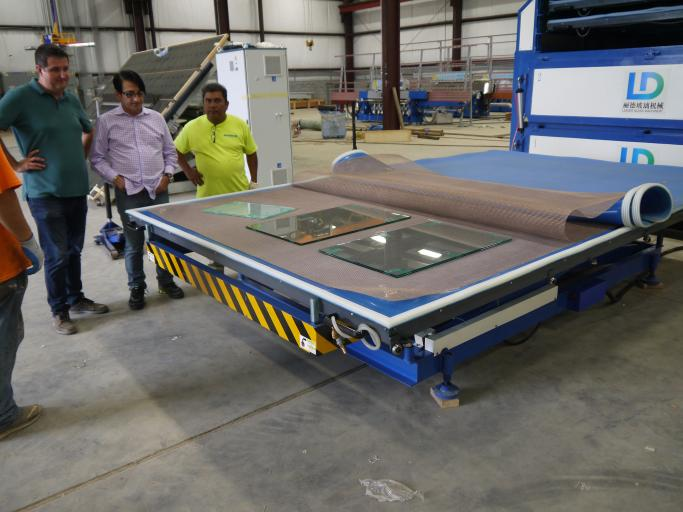

Loading pictures

Customer plant

Customer satisfaction

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for 2022 High quality Laminated Glass Production Line - laminated glass machine 4 layers – leader , The product will supply to all over the world, such as: Moscow, UK, Slovak Republic, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.